| Kharkiv model V-2 | |

|---|---|

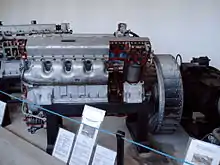

Engine (V-2-34) of Soviet T-34 tank displayed in the Finnish Tank Museum (Panssarimuseo) in Parola. Some parts have been removed or cut to show the inner workings | |

| Layout | |

| Configuration | V-12 |

| Displacement | 38.8 L (2,370 cu in) |

| Cylinder bore | 150 mm (5.9 in) |

| Piston stroke |

|

| Combustion | |

| Fuel type | Diesel |

| Output | |

| Power output | 340–520 kW (460–700 bhp) |

| Torque output | 220 kgf⋅m (2,157 N⋅m; 1,591 lbf⋅ft) |

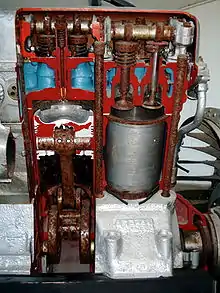

The Kharkiv model V-2 (Russian: В-2) was a Soviet diesel tank V-12 engine, the V angle at 60°, with dual overhead camshafts per bank, four valves per cylinder opened by bucket-style followers and direct fuel injection, features found on modern high-performance diesel engines. Designed at the Kharkiv Locomotive Factory by Konstantin Chelpan and his team, it is found in the BT-7M (BT-8), T-34, KV, IS and IS-10 (T-10) tanks, and by extension, the vehicles based on them, such as the SU-85 and SU-100 tank destroyers based on the T-34 and the ISU-122 and ISU-152 self-propelled guns based on the IS-2. Throughout its production life, output ranged from roughly 450-700 hp.

History of development and production

The V-2 was in development from 1931 until 1939 by the design team of the diesel department of the Kharkiv Locomotive Works, first under the leadership of Konstantin Chelpan, who was arrested in 1938. Work was passed down to his deputy for project work, Yakov Efimovich Vikhman, and Ivan Yakovlevich Trashutin, his deputy for experimental and production work, who completed development of the engine in 1939.

Serial production for the V-2 begun on September 1, 1939. The Red Army adopted the V-2 engine in the same year in three modifications: the V-2 (500hp), the V-2K (600hp) for the KV line of tanks and the V-2V (375hp).[1]

Near the end of the 20th century, the V-2 was fitted with more modern modifications by the chief designer of the head design bureau for the Chelyabinsk Tractor Plant, Vladimir Ivanovich Butov.

Description

The engine was made of aluminium with a closed water-cooling system. It included a water jacket of the cylinder blocks, radiators, a water pump, a centrifugal fan, a T-valve with steam and air valves, and piping. The cooling system capacity was 90–95 liters. The radiators were connected to the surrounding air via an air valve. The T-valve, leading to both radiators, was designed for filling the cooling system with coolant.

Variants

- V-2: Initial production version, 1937. Used in the BT-7M (BT-8).

- V-2-34: V-2 with revised hull mounts, fuel and cooling connectors and refined clutch, 1939. Used in the T-34, SU-85 and SU-100, it produced 500 hp (370 kW) @ 1800 RPM.[2] The following units were attached to the engine: fuel feed pump; fuel filter; fuel pump NK-1; high-pressure fuel line; oil pump; oil filter; water pump, and alternator. The starting of the engine could be carried out using the electric starter ST-700 (the main method), or compressed air (the alternate method) using the two air cylinders located in the driver’s compartment.

- V-2K: V-2 with increased injection pressure and higher engine speed, 1939. Used in the KV-1 and KV-2, it produced 600 hp at 2,000 rpm.

- V-2V: V-2 detuned for use in lighter vehicles, 1940. Used in the Voroshilovets artillery tractor, it produced 375 hp.

- V-2L/P: V-2 modified for boats, not built.

- V-2SN (Нагнетатель системы, supercharger systems): V-2 with a supercharger from the Mikulin AM-38 aircraft engine, 1940. Used in the KV-3, it produced 862 hp.

- V-2-10 (V-2IS): V-2 with stronger cylinders and heads, improved fuel pump, larger radiator and oil cooler and modified hull mounts, 1943. Used in the IS-1, IS-2, ISU-122 and ISU-152, it produced 520 hp.

- V-2-450AV-S3: V-2 modified for oil drilling equipment, it produced 450 hp.

- V-4: Basically a V-2 engine cut in half to form an inline six engine. Used in the T-50 light tank, it produced 300 hp.

- V-11: Used in the IS-3; It produced 520 hp. Developed into the V-44, used in the T-44.

- V-12: Used in the IS-4. Fitted with a supercharger, it produced 750 hp. Produced in small numbers due to its extreme unreliability.

- V-12-5: Improved V-12, used in the T-10, it produced 700 hp.

- V-46: Used in the T-72, T-72M, T-62M-1 and the 2K22 Tunguska. It produced 780 hp; the Tunguska used a 710 hp version.

- V-54: Used in the T-54, it produced 520 hp.

- V-55: Used in the T-55, it produced 580 hp.

- V-55V: Used in the T-62, it produced 580 (later 620) hp.

- V-84: Used in the T-72A, T-72B, 2S19 Msta-S and the T-90. It produced 840 hp; the Msta-S used a 780 hp version.

- V-92: Used in the T-90A, 2S35 Koalitsiya-SV and T-90M.

- V-401: Detuned version of the V-54 for the AT-T artillery tractor, it produced 415 hp.

Manufacturers

Before the 2nd World War, it was produced only at Engine Plant No. 75 (a branch of the Kharkov Locomotive Plant), the contractors were KhTZ , Chelyabinsk and Kirov (Leningrad) plants.

After the start of the war, it was produced at the Stalingrad Tractor Plant and in Sverdlovsk at Plant No. 76. In October 1941, Plant No. 75 was evacuated to Chelyabinsk to the ChTZ site. The Kirov plant also moved there. All of them were united into a huge Tankograd. This plant became the main manufacturer of the V-2 during the war (about 50 thousand engines, including engines produced in Kharkov). Later, in 1942, production of the V-2 was also mastered at plant No. 77 in Barnaul .

As of 2022, production of modifications of the V-2 engine continues at the Chelyabinsk Tractor Plant, Barnaultransmash and the Ural Diesel Engine Plant.

See also

- Maybach HL230, equivalent contemporary German tank engine

- Rolls-Royce Meteor, equivalent contemporary British tank engine

References

- Notes

- ↑ "В-2: путь в серию".

- ↑ Hughes & Mann 1999, p. 34.

- Sources

- Hughes, Matthew; Mann, Chris (1999). The T-34 Russian Battle Tank. Wisconsin: MBI Publishing Company. ISBN 9780760307014.