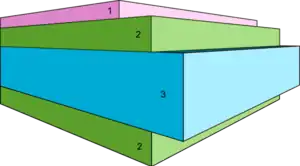

FBB construction:

1 – Coating

2 – Bleached chemical pulp

3 – Mechanical pulp

4 – Unbleached/Bleached chemical pulp

1 – Coating

2 – Bleached chemical pulp

3 – Mechanical pulp

4 – Unbleached/Bleached chemical pulp

Folding boxboard, also referred to as FBB or by the DIN Standard 19303 codes of GC or UC, is a paperboard grade made up of multiple layers of chemical and mechanical pulp.[1] This grade is made up of mechanical pulp in between two layers of chemical pulp. The top layer is of bleached chemical pulp with an optional pigment coating.[2] This is a low-density material with high stiffness and a slightly yellow colour, mainly on the inside. The major end uses of folding boxboard are health and beauty products, frozen, chilled and other foods, confectionaries, pharmaceuticals, graphical uses[3] and cigarettes.[4]

See also

References

- ↑ Iggesund Paperboard (2008). "Product Catalogue: General Technical Information". Archived from the original on 2011-07-13. Retrieved 2009-07-18.

- ↑ Iggesund Paperboard AB (2008). "Paperboard the Iggesund Way": 11.

{{cite journal}}: Cite journal requires|journal=(help) - ↑ Stora Enso (2009). "Wide selection of boards for consumer goods". Archived from the original on 2009-07-01. Retrieved 2009-08-06.

- ↑ Iggesund Paperboard (2008). "Incada". Retrieved 2009-08-06.

This article is issued from Wikipedia. The text is licensed under Creative Commons - Attribution - Sharealike. Additional terms may apply for the media files.