A low magnetic electric motor (or non magnetic electric motor) is an AC or DC motor with a reduced magnetic stray field signature.

Description

Low magnetic or nonmagnetic electric[1] motors are used on board mine countermeasures vessels, minehunters, minesweepers and specific types of submarines. For about a hundred years sea mines or naval mines have been an established element in naval warfare. Modern naval mines nowadays react on magnetic, acoustic and pressure signals. By far the most important step in their development was the invention of the magnetic influence firing principle, which utilizes the magnetic interference field of passing ships. Naval mines with magnetic fuzes are effective, inexpensive and easy to deploy. An electric motor produces two types of magnetic fields: a dynamic alternating stray field, whilst running and a static remnant or residual magnetic during standstill. To avoid detection it is necessary to reduce[2][3][4][5] these signatures at the source as much as possible.

Signature

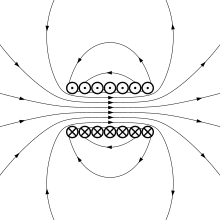

Electric motors generate internal magnetic fields to rotate the rotor in the stator. A significant part of these magnetic stray fields emanate to the outside of the electric motor housing and can be measured and/or detected.[6] During running an electric motor also produce air borne and structure borne noises. The primary goal to avoid detection is to reduce these signatures as much as possible, to be able to operate in stealth mode. The measurements of ships' signature as a whole are usually performed at a magnetic ranging facility.

Low magnetic

Low magnetic motors or nonmagnetic electric motors are designed to provide a reduced emanating magnetic stray field signature.[7][8] These electric motors are manufactured from as little magnetic material as possible. The parts and components used to manufacture these electric motors are selected from materials with a low magnetic permeability. There are three major means of reducing the emanating magnetic stray fields of an electric motor: a dedicated electric and magnetic layout, electromagnetic shielding and additional compensating coils.[9][10] Reduction and ways to achieve this are described in the American standard DOD-STD-2146,[11] the British Defence-Standard[12] 02-717[13] and the German Standard BV3013.[14] Further reduction to the electric motors' magnetic signature, as well as the reduction of the ships' magnetic signature can be obtained by additional degaussing coils.

Airborne Noise

The primary source of air borne noise from an electric motor is the cooling fan to provide air to the electric motor. Reduction of air borne noise can be achieved by reducing the cooling air speed. An alternative is to use water or oil cooled electric motors. Air borne noise levels for different type of equipment on board Navy Vessels are laid down in the American military standard[15] MIL-STD-1474D,[16] the British Defence Standard 02-813[17] or the Indian Naval Engineering Standard NES 847.

Structure Borne Noise

Structure borne noise in an electric motor is the result of roller bearing inaccuracies, rotor bar pass frequencies, magnetic unbalance, non-matching rotor and stator slot combinations, providing acoustic signals. Reducing structure borne noise can be done by various means. A correct rotor/stator slot combination, selected precision roller bearings, reduced magnetic saturation in the stator can help to reduce the structure borne noise levels. Methods of measurements and acceptance criteria are defined in the American military MIL-STD-740-2(SH)[18] and the British Defence Standard 02-813[19]

Vibration (internally exited)

Mechanical unbalance of the rotor will generate vibration. The vibration will result in structure borne noise, as well as unwanted acceleration forces or resonance, which eventually will harm or damage parts of the electric motor. To reduce the unbalance forces, precision balancing, as described in the American military standard MIL-STD-167-1A,[20] type I (internally exited) will be necessary.

Vibration (externally exited)

Electric motors on board naval vessel may experience shock and vibration. A dedicated rigid design will allow electric motors to withstand these environmental impacts and provide sufficient active hardening. Passive hardening is done by installation of shock and vibration mounts onto the motor and/or system. Test method and limits are described in the American standard MIL-STD-167-1A, type II (environmental).

Shock

Due to the nature of naval applications, equipment on board of mine countermeasures vessels and submarines may be subject to underwater explosions. Therefore, low magnetic electric motors need to be shock proof or shock resistant.[21] Naval shock requirements on ships are specified in standards, such as the American standard NAVSEA-908-LP-000-3010 (Rev 1).[22] Equipment on board of naval vessels is specified in different standards, such as the American military standard MIL-S-901D, the British and Indian[23][24] naval standard BR3021 or the German standard BV 0230. A large part of the environmental tests and measurements are stipulated in the American standard MIL-STD-810. Shock testing on equipment is performed by specialist institutes, such as TNO,[25] NTS Navy, Thales-ECC or QinitiQ.

Users

_shock_trials.jpg.webp)

- Osprey-class minehunter

- Tripartite-class minehunter

- Huon-class minehunter

- Oksøy-class minehunter

- Alta-class minesweeper

- Sandown-class minehunter

- Lerici-class minehunter

- Katanpää-class minehunter

- Kormoran 2-class minehunter

- Visby-class korvette

References

- ↑ MIL-DTL-17060G(SH), MOTOR, ALTERNATING CURRENT, INTEGRAL-HORSEPOWER, SHIPBOARD USE, Nonmagnetic motors.

- ↑ Holmes, John J. (2006). Exploitation of a Ship's Magnetic Field Signatures. Morgan & Claypool Publishers. ISBN 9781598290745.

- ↑ Holmes, John J. (2008). Reduction of a Ship's Magnetic Field Signature. Morgan & Claypool Publishers. ISBN 9781598292480.

- ↑ MAGNETIC SILENCING REQUIREMENTS FOR THE CONSTRUCTION OF NONMAGNETIC SHIPS AND CRAFT (METRIC), Department of Defense

- ↑ B. Froidurot, L.-L. Rouve, A. Foggia, J.-P. Bongiraud, G. Meunier (2002). "Magnetic Discretion of Naval Propulsion Machines" (PDF). Institute of Electrical and Electronics Engineers. Archived from the original (PDF) on 2017-09-06. Retrieved 2017-09-06.

{{cite web}}: CS1 maint: multiple names: authors list (link) - ↑ Clarke, David (April 2006). "Magnetic Signature of Brushless Electric Motors". Australian Government Department of Defence, Defence Science and Technology Organisation.

- ↑ Hasper, H. (September 1999). ""Reduction of Magnetic Strayfield from Squirrel-cage Induction Motors", COMBIMAC document, 02 91". IEEE Transactions on Energy Conversion. 14 (3): 628–632. Bibcode:1999ITEnC..14..628L. doi:10.1109/60.790926.

- ↑ Le Coat, G. (1999). "Electromagnetic signature of induction machines". IEEE Transactions on Energy Conversion. 14 (3): 628–632. Bibcode:1999ITEnC..14..628L. doi:10.1109/60.790926.

- ↑ Cope, C. (1996). "Low Magnetic Signature Propulsion System" (PDF). Engineering Matters.

- ↑ "Poor scattering field electrical machine". Google Patents. 17 November 1988.

- ↑ DIRECT CURRENT GENRATORS AND MOTORS, LOW STRAY FIELD, DESIG OF (METRIC), Department of Defense

- ↑ "UK Defence Standardization". Ministry of Defence.

- ↑ Design Guide and Requirements for Equipment to Achieve a Low Magnetic Signature, Ministry of Defence.

- ↑ AMAGNETISCH UND STREUFELDARME BAUWEISE, Zur Bauvorschrift für Schiffe der Bundeswehr.

- ↑ "Military Standards". Assist.

- ↑ NOISE LIMITS, DESIGN CRITERIA, Department of Defense

- ↑ Requirements for Structure Borne Vibration and Airborne Noise Testing of Warship Equipment, Ministry of Defence

- ↑ STRUCTUREBORNE VIBRATION ACCELERATION MEASUREMENTS AND ACCEPTANCE CRITERIA OF SHIPBOARD EQUIPMENT, Department of Defense

- ↑ "Requirements for Structure Borne Vibration and Airborne Noise Testing of Warship Equipment". Ministry of Defence.

- ↑ MECHANICAL VIBRATIONS OF SHIPBOARD EQUIPMENT, Department of Defense

- ↑ ANG Boon Hwee, HAN Mingguang Jeremy (2013–2014). "MANAGING SHOCK REQUIREMENTS OF SHIPBOARD EQUIPMENT" (PDF). Defence Science Technology Agency, Singapore.

- ↑ "Shock Design Criteria for Surface Ships (PDF". Assist.

- ↑ "Guidelines on Shock Standard and Shock Testing of Naval Electronic/Electrical Equipment" (PDF). DGQA. Archived from the original (PDF) on 2017-11-07. Retrieved 2017-07-20.

- ↑ "Naval Engineering Standard (NES) / Indian Navy (IN)". Indian Navy.

- ↑ "SHOCK AND VIBRATION" (PDF). TNO.