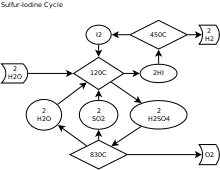

The sulfur–iodine cycle (S–I cycle) is a three-step thermochemical cycle used to produce hydrogen.

The S–I cycle consists of three chemical reactions whose net reactant is water and whose net products are hydrogen and oxygen. All other chemicals are recycled. The S–I process requires an efficient source of heat.

Process description

| H2O | ½ O2 | |||||

| ↓ | ↑ | |||||

| I2 | → | Reaction 1 | ← | SO2 + H2O | ← | Separate |

| ↑ | ↓ | ↑ | ||||

| 2 HI | ← | Separate | → | H2SO4 | → | Reaction 2 |

| ↓ | ||||||

| H2 |

The three reactions combined to produce hydrogen are the following:

- I2 + SO2 + 2 H2O 2 HI + H2SO4 (120 °C (250 °F)) (Bunsen reaction)

- The HI is then separated by distillation or liquid/liquid gravitic separation.

- The water, SO2 and residual H2SO4 must be separated from the oxygen byproduct by condensation.

- 2 HI I2 + H2 (450 °C (840 °F))

- Iodine and any accompanying water or SO2 are separated by condensation, and the hydrogen product remains as a gas.

- Net reaction: 2 H2O → 2 H2 + O2

The sulfur and iodine compounds are recovered and reused, hence the consideration of the process as a cycle. This S–I process is a chemical heat engine. Heat enters the cycle in high-temperature endothermic chemical reactions 2 and 3, and heat exits the cycle in the low-temperature exothermic reaction 1. The difference between the heat entering and leaving the cycle exits the cycle in the form of the heat of combustion of the hydrogen produced.

Characteristics

Advantages

- All fluid (liquids, gases) process, therefore well suited for continuous production

- High thermal efficiency predicted (about 50%)

- Completely closed system without byproducts or effluents (besides hydrogen and oxygen)

- Suitable for application with solar, nuclear, and hybrid (e.g., solar-fossil) sources of heat - if high enough temperatures can be achieved

- More developed than competing thermochemical processes

- Scalable from relatively small scale to huge applications

- No need for expensive or toxic catalysts or additives

- More efficient than electrolysis of water (~70-80% efficiency) using electricity derived from a thermal power plant (~30-60% efficiency) combining to ~21-48% efficiency

- Waste heat suitable for district heating if cogeneration is desired

Disadvantages

- Very high temperatures required (at least 850 °C (1,560 °F)) - unachievable or difficult to achieve with current pressurized water reactors or concentrated solar power

- Corrosive reagents used as intermediaries (iodine, sulfur dioxide, hydriodic acid, sulfuric acid); therefore, advanced materials needed for construction of process apparatus

- Significant further development required to be feasible on large scale

- At the proposed temperature range advanced thermal power plants can achieve efficiencies (electric output per heat input) in excess of 50% somewhat negating the efficiency advantage

- In case of leakage corrosive and somewhat toxic substances are released to the environment - among them volatile iodine and hydroiodic acid

- If hydrogen is to be used for process heat the required high temperatures make the benefits compared to direct utilization of heat questionable

- Unable to use non-thermal or low-grade thermal energy sources such as hydropower, wind power or most currently available geothermal power

Research

The S–I cycle was invented at General Atomics in the 1970s.[1] The Japan Atomic Energy Agency (JAEA) has conducted successful experiments with the S–I cycle in the Helium cooled High Temperature Test Reactor,[2][3][4][5] a reactor which reached first criticality in 1998, JAEA have the aspiration of using further nuclear very high-temperature generation IV reactors (VHTR) to produce industrial scale quantities of hydrogen. (The Japanese refer to the cycle as the IS cycle.) Plans have been made to test larger-scale automated systems for hydrogen production. Under an International Nuclear Energy Research Initiative (INERI) agreement, the French CEA, General Atomics and Sandia National Laboratories are jointly developing the sulfur-iodine process. Additional research is taking place at the Idaho National Laboratory, in Canada, Korea and Italy.

Material challenge

The S–I cycle involves operations with corrosive chemicals at temperatures up to about 1,000 °C (1,830 °F). The selection of materials with sufficient corrosion resistance under the process conditions is of key importance to the economic viability of this process. The materials suggested include the following classes: refractory metals, reactive metals, superalloys, ceramics, polymers, and coatings.[6][7] Some materials suggested include tantalum alloys, niobium alloys, noble metals, high-silicon steels,[8] several nickel-based superalloys, mullite, silicon carbide (SiC), glass, silicon nitride (Si3N4), and others. Recent research on scaled prototyping suggests that new tantalum surface technologies may be a technically and economically feasible way to make larger scale installations.[9]

Hydrogen economy

The sulfur-iodine cycle has been proposed as a way to supply hydrogen for a hydrogen-based economy. It does not require hydrocarbons like current methods of steam reforming but requires heat from combustion, nuclear reactions, or solar heat concentrators.

See also

Footnotes

- ↑ Besenbruch, G. 1982. General Atomic sulfur iodine thermochemical water-splitting process. Proceedings of the American Chemical Society, Div. Pet. Chem., 27(1):48-53.

- ↑ "HTTR High Temperature engineering Test Reactor". Httr.jaea.go.jp. Retrieved 23 January 2014.

- ↑ https://smr.inl.gov/Document.ashx?path=DOCS%2FGCR-Int%2FNHDDELDER.pdf. Progress in Nuclear Energy Nuclear heat for hydrogen production: Coupling a very high/high temperature reactor to a hydrogen production plant. 2009

- ↑ Status report 101 - Gas Turbine High Temperature Reactor (GTHTR300C)

- ↑ JAEA’S VHTR FOR HYDROGEN AND ELECTRICITY COGENERATION : GTHTR300C

- ↑ Paul Pickard, Sulfur-Iodine Thermochemical Cycle 2005 DOE Hydrogen Program Review

- ↑ Wonga, B.; Buckingham, R. T.; Brown, L. C.; Russ, B. E.; Besenbruch, G. E.; Kaiparambil, A.; Santhanakrishnan, R.; Roy, Ajit (2007). "Construction materials development in sulfur–iodine thermochemical water-splitting process for hydrogen production". International Journal of Hydrogen Energy. 32 (4): 497–504. doi:10.1016/j.ijhydene.2006.06.058.

- ↑ Saramet info sheet Archived 14 February 2006 at the Wayback Machine

- ↑ T. Drake, B. E. Russ, L. Brown, G. Besenbruch, "Tantalum Applications For Use In Scale Sulfur-Iodine Experiments", AIChE 2007 Fall Annual Meeting, 566a.

References

- Paul M. Mathias and Lloyd C. Brown "Thermodynamics of the Sulfur-Iodine Cycle for Thermochemical Hydrogen Production", presented at the 68 th Annual Meeting of the Society of Chemical Engineers, Japan 23 March 2003. (PDF).

- Atsuhiko TERADA; Jin IWATSUKI, Shuichi ISHIKURA, Hiroki NOGUCHI, Shinji KUBO, Hiroyuki OKUDA, Seiji KASAHARA, Nobuyuki TANAKA, Hiroyuki OTA, Kaoru ONUKI and Ryutaro HINO, "Development of Hydrogen Production Technology by Thermochemical Water Splitting IS Process Pilot Test Plan", Journal of Nuclear Science and Technology, Vol.44, No.3, p. 477–482 (2007). (PDF).

External links

- Hydrogen: Our Future made with Nuclear (in MPR Profile issue 9)

- Use of the modular helium reactor for hydrogen production (World Nuclear Association Symposium 2003)