| |||

| |||

| Names | |||

|---|---|---|---|

| IUPAC name

trichlorosilane | |||

| Other names

silyl trichloride, silicochloroform | |||

| Identifiers | |||

3D model (JSmol) |

|||

| ChemSpider | |||

| ECHA InfoCard | 100.030.026 | ||

| EC Number |

| ||

PubChem CID |

|||

| RTECS number |

| ||

| UNII | |||

| UN number | 1295 | ||

CompTox Dashboard (EPA) |

|||

| |||

| |||

| Properties | |||

| HCl3Si | |||

| Molar mass | 135.45 g/mol | ||

| Appearance | colourless liquid | ||

| Density | 1.342 g/cm3 | ||

| Melting point | −126.6 °C (−195.9 °F; 146.6 K) | ||

| Boiling point | 31.8 °C (89.2 °F; 304.9 K) | ||

| hydrolysis | |||

| Hazards[1] | |||

| GHS labelling: | |||

| |||

| Danger | |||

| H224, H250, H302, H314, H332 | |||

| P231, P280, P305+P351+P338+P310, P310, P370+P378 | |||

| NFPA 704 (fire diamond) | |||

| Flash point | −27 °C (−17 °F; 246 K) | ||

| 185 °C (365 °F; 458 K) | |||

| Explosive limits | 1.2–90.5% | ||

| Safety data sheet (SDS) | ICSC 0591 | ||

| Related compounds | |||

Related chlorosilanes |

Chlorosilane Dichlorosilane Dichloromethylsilane Chlorodimethylsilane Silicon tetrachloride | ||

Related compounds |

Trifluorosilane Tribromosilane Chloroform | ||

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

Infobox references | |||

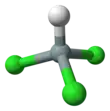

Trichlorosilane is an inorganic compound with the formula HCl3Si. It is a colourless, volatile liquid. Purified trichlorosilane is the principal precursor to ultrapure silicon in the semiconductor industry. In water, it rapidly decomposes to produce a siloxane polymer while giving off hydrochloric acid. Because of its reactivity and wide availability, it is frequently used in the synthesis of silicon-containing organic compounds.[2]

Production

Trichlorosilane is produced by treating powdered metallurgical grade silicon with blowing hydrogen chloride at 300 °C. Hydrogen is also produced, as described in the chemical equation:

- Si + 3 HCl → HCl3Si + H2

Yields of 80-90% can be achieved. The main byproducts are silicon tetrachloride (chemical formula SiCl4), hexachlorodisilane (Si2Cl6) and dichlorosilane (H2SiCl2), from which trichlorosilane can be separated by distillation.

It is also produced from silicon tetrachloride:[3]

- Si + 3 SiCl4 + 2 H2 → 4 HCl3Si

Applications

Trichlorosilane is the basic ingredient used in the production of purified polysilicon.

- HCl3Si → Si + HCl + Cl2

Ingredient in hydrosilylation

Via hydrosilylation, trichlorosilane is a precursor to other useful organosilicon compounds:

- RCH=CH2 + HSiCl3 → RCH2CH2SiCl3

Some useful products of this or similar reactions include octadecyltrichlorosilane (OTS), perfluoroctyltrichlorosilane (PFOTCS), and perfluorodecyltrichlorosilane (FDTS). These reagents used in surface science and nanotechnology to form Self-assembled monolayers. Such layers containing fluorine decrease surface energy and reduce sticking. This effect is usually exploited as coating for MEMS and microfabricated stamps for a nanoimprint lithography (NIL) and in injection molding tools.[4]

Organic synthesis

Trichlorosilane is a reagent in the conversion of benzoic acids to toluene derivatives. In the first step of a two-pot reaction, the carboxylic acid is first converted to the trichlosilylbenzyl compound. In the second step, the benzylic silyl derivative is converted to the toluene derivative with base.[5]

Safety

Trichlorosilane is highly reactive, and may respond violently (and even explosively) to many compounds.[6] This also includes water, potentially producing silicon dioxide, chlorine, hydrogen, hydrogen chloride (and it's aqueous form hydrochloric acid), and heat. Trichlorosilane can cause hazardous chemical reactions with moisture and humidity alone, and should be handled and stored under inert gas.[6] Spills of trichlorosilane may be neutralized using a 1-1 ratio of sodium hydroxide, or a 2-1 ratio of sodium bicarbonate to trichlorosilane.[7] Fires can be extinguished using alcohol-resistant aqueous film-forming foam (AR-AFFF).[6][7]

References

- ↑ "GESTIS-Stoffdatenbank". gestis.dguv.de.

- ↑ Lianhong Xu, Ravi Kurukulasuriya, "Trichlorosilane" Encyclopedia of Reagents for Organic Synthesis, 2006. doi:10.1002/047084289X.rt213.pub2

- ↑ Simmler, W. "Silicon Compounds, Inorganic". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a24_001. ISBN 978-3527306732.

- ↑ Cech J, Taboryski R (2012). "Stability of FDTS monolayer coating on aluminum injection molding tools". Applied Surface Science. 259: 538–541. Bibcode:2012ApSS..259..538C. doi:10.1016/j.apsusc.2012.07.078.

- ↑ George S. Li, David F. Ehler, R. A. Benkeser "Methyl Groups By Reduction Of Aromatic Carboxylic Acids With Trichlorosilane - Tri-n-propylamine: 2-methylbiphenyl" Org. Synth. 1977, volume 56, pp. 83. doi:10.15227/orgsyn.056.0083

- 1 2 3 Trichlorosilane: Safety Data Sheet P-4823 (PDF) (Report). Linde Inc. February 3, 2022. Archived from the original (PDF) on June 6, 2022.

- 1 2 Hazardous Substance Fact Sheet: Trichlorosilane (PDF) (Report). New jersey department of health. October 2010.